Use this hydraulic and pneumatic cylinder calculator to calculate every piece of information. Easily calculate the cylinder characteristics such force, stroke times, velocity and volume. But let’s not stop there.

This calculator will give your the force, velocity, stroke time for extension and retraction. It also calculates port sizes, burst pressure, critical buckling load and material strengths for a wide variety of cylinder types. It also handles regeneration, buckling support and external loads.

Everything you need to know in this simple and FREE online calculator.

Remove ads. Save your Data. Work Offline Go Pro Today!

|

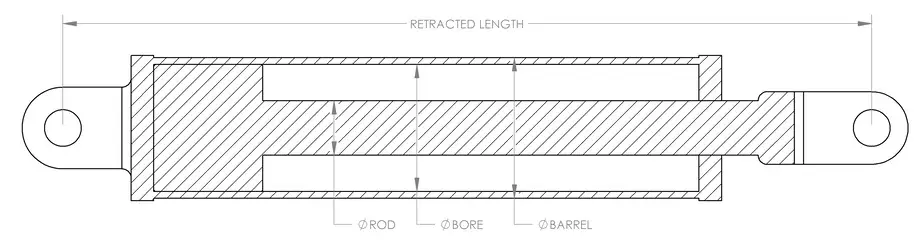

Notes: 1. For trunion cylinders, the retracted length is the distance from the rod clevis to the first mounting point. 2. A traditional cylinder is considered supported if the barrel is constrained from translation at the head. 3. A trunion cylinder is considered supported if the free end is prevented from translating. 4. Contact your local cylinder manufacturer about applicable standards for cylinder approval. 5. While every effort has been made to ensure the accuracy of this cylinder calculator, The Mentored Engineer does not assume responsibility for designs produced from it or any adherance to any standard. |