I used to drive a 2001 Saturn SL and as the car got up to 60 mph (95 kph) the tires were unbalanced and would shake the car. As I got up to 70 mph (113 kph) the car didn’t shake anymore.

All tires have a slight imbalance to them. The magnitude and location of the imbalance determines the tire’s natural frequency. When the tire is operated at or near the natural frequency the vibration increases dramatically. Increasing or decreasing speed will eliminate the vibration.

The car as a whole can be analyzed as a complex vibration problem. Items in the system that need to be considered are the imbalance and its location in the wheel, the rotation speed, the weight of the wheel and how the wheel attaches to the car via suspension.

Natural Frequency

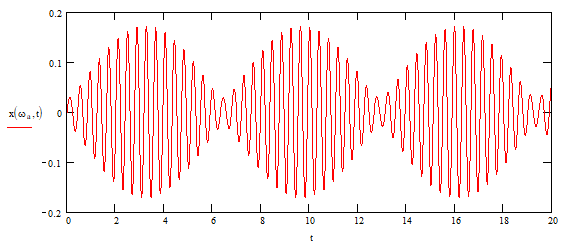

When all this is known, we can calculate the natural frequency of the tire. The natural frequency is the speed at which the tire will naturally vibrate. The image below shows the natural vibration amplitude of a beam vibrating.

When the car operated at this frequency, the amplitude of the vibration to continually increase without bound.

The Linear Assumption

Mathematically this is correct but in actuality, there are many factors that will limit the vibration amplitude. To simplify calculations, we assume things like shocks, struts and springs have linear properties. For the most part, this is true. However, they are only linear in the intended operating range.

As the strut or shock reaches the end of the stroke, your linear assumption meets an abrupt increase. The same thing happens when a spring is fully collapsed.

There are lots of variables that come together so that even when I operate my Saturn at 60 mph, it doesn’t fall apart.

Finding the Natural Frequency

So, I’m not nerd enough to try to model out my car’s natural frequency. It probably would have taken me months to calculate all the variables.

No, I simply drove my car and found the vibration at 60 mph.

Beating

To be honest, it is near impossible to operate something at the natural frequency perfectly without complex controls. Often, we get a similar phenomenon when we operate near the natural frequency.

If system is being forced to rotate at a slightly different frequency than the natural frequency. The result is called beating. Beating is when the amplitudes will add together for some time and then cancel each other out a little later.

When stopped at a traffic light, I sometimes notice several cars in front of me with their blinkers on. The blinkers usually don’t flash at the same rate. For a brief period, they are in sync, but soon enough they are out of sync again. This is another example of beating.

In a car, the vibration will come and go over several seconds. In the case above, it will happen about every 6.5 seconds with the worst of it lasting for about 2.5 seconds.

Beating is not good for your tires or car. It will cause the tires to wear quickly as well as the suspension components. Prolonged beating may cause further damage to the car’s internal structure.

When I noticed the beating in my Saturn, I took it into the shop for a balancing. Too late, the beating already wore the tire through in one spot to the steel wire reinforcement.

Altering the Natural Frequency

Natural Frequency Is Outside of Operating Range

Depending on your system, you may have several natural frequencies to begin with. In an ideal world, we would want these frequencies to be outside of the normal operating range.

For a car, if you had a natural frequency at 100 mph, this might not ever be and issue because we don’t drive at or near that speed often. However, if you are a race car driver, this might be a speed that you are at quite often.

Balance the Tire

The main way to alter the natural frequency is to balance the tire. There are complex machines that do that quite accurately. These machines tell an operator exactly how much weight to add and where. Amazing.

In my early career, I worked on a project that pulverized railroad ties (about 800 hp). It was a large machine that had many teeth on a rotating head. When we started it up, it had a major vibration issue.

We ended up disassembling all the teeth and weighing them. At this point we rearranged the teeth so that the machine was more balanced than before. When we started it back up, the vibration was at an acceptable level.

Don’t Run at That Speed

One final way to avoid the natural frequency is to quickly accelerate and decelerate through the natural frequency. My brother is a naval engineer and his senior project was to develop a hull and propulsion system for a new ship.

He mentioned that the ships propeller had two natural frequencies in the operational range. These frequencies were not at normal cruising speeds so they would add controls to not allow the propellers operated at certain speeds. The controls would quickly accelerate the propeller through each natural frequency. This minimized any damage that could be done to the ship.

In Summary

Tires seem to be more imbalanced at certain speeds because they are being operated at or near the natural frequency. This will cause damage to your tire, suspension and possibly the frame of your car. Change your speed so that you are not operating at that speed.

Go get your tires balanced….