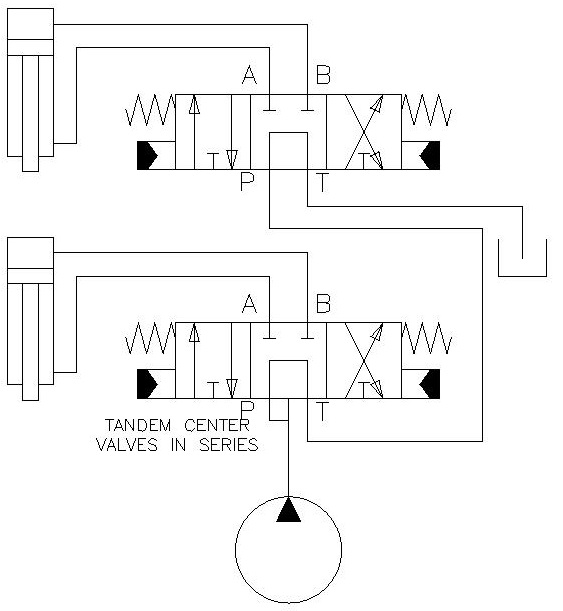

The log splitter that I own has two control valves on it. Both are tandem center and connected in series. I wanted to explain why this is a bad idea and should be avoided.

Tandem center directional control valves have the P and T ports connected in the center position. The way they are connected in series is to have the tank line from the first valve supplying the P port for the second valve. This repeats for as many valves as are in the series. This can cause increases or decreases in pressure and limits your supply of oil. Basically, the results are unpredictable.

Let me dive deeper.

I recently wrote an article on directional control valves. In it, I mentioned briefly what a tandem valve center is and how it is a bad thing if you have multiple valves connected in series. So, on our log splitter we have this bad situation. But really, in practice it isn’t such a big deal on this piece of equipment because it is rare that I am going to be operating the jib and the splitter mechanism at the same time. For this reason, I haven’t changed the valve configuration.

But I still want to illustrate what would happen if I did need to operate two (or more) functions at once.

Pressure Intensification

In this hydraulic system, I’ve got my pump putting out oil and the first stop is the valves. With both valves centered, oil is flowing through the first valve and coming out the tank line and going into the second valve and coming out the tank. Good so far.

If I shift the first valve so that P and A are connected, what I do is send oil from the B port of this valve back through the tank line which flows into the pressure line of the second line. Then if I decide to use the second valve, I am going to be using oil from the B port, not from the pump, to be doing the work. So the question you should be asking is, what is going on between the A and B ports?

You can probably already see the issue, but let me tell you why this would get a little wonky. Let’s say I am going to shift my valve so that P and A are connected. What I am doing is pressurizing a line causing a cylinder to retract. I have 3,000 PSI available from the pump and I have a two to one ratio on this cylinder. So that means my system pressure of 3,000 PSI is maintained and the cylinder multiplies the pressure to 6,000 PSI (2:1 ratio). Ouch! That is a problem!

What happens if I now grab the other valve and shift it so that pressure can build on the P port of the second valve? This could happen if I am trying to pull a stump out of the ground while trying to split at the same time.

I know highly unlikely, but theoretically it could happen and there are many other situations where you might need to operate two cylinders. Anyway, I can build up 6,000 PSI before the first cylinder stalls out.

So I have the ability to intensify pressure, even above system pressure, and create unwanted operation of the system. I doubt my tank port on my valve is rated for that. I also doubt that the hose or cylinder ports are rated for that. This leads to damage of components, line breakage or potential bodily harm. Small holes in hydraulic hoses can shoot oil out that can cut through skin. You definitely don’t what to get it in your blood stream.

Anyway, back to the issue at hand. So, there are many potential issues with pressure intensification. Remember that if only one handle is pulled, there is no issue, but if another valve is shifted, we can create high pressures or…

Low Pressure

Our second problem exists if we operate the first valve the other way. I now put 3,000 PSI into my two to one ratio cylinder. With 3000 psi in, I am only getting out 1500 PSI out of the tank port. I have cut my available pressure in half! Furthermore, if the cylinder is doing any load lifting, I’m going to lose even more pressure.

So now if I activate another valve, let’s just say I am trying to lift a load on the jib. If that takes more than 1,500 PSI it’s just going to stall. If there is enough pressure to open the load holding valve, it may even fall. So that’s another problem with using tandem center valves in series: I don’t have enough pressure to do what I need to do.

Limited Oil

With a system of two cylinders like the log splitter, there is only a finite volume of oil available. When I shift the valve on the first section, I will eventually either fully extend or retract the cylinder. At that point there is no oil available for the other valves.

If I continue to keep the valve shifted, I am going to blow over my relief valve and potentially overheat the oil. Even if I wanted to intensify the pressure, I could only do it for a few seconds or so. This is the third reason why we don’t want to use tandem centers with multiple valves.

These three hazards increase and intensify with each valve section added. If you are coordinated enough to control 4 sections, you may get very unpredictable pressures and unit performance. As good engineers, we need to avoid this possibility altogether though. Luckily, there is a readily available solution.

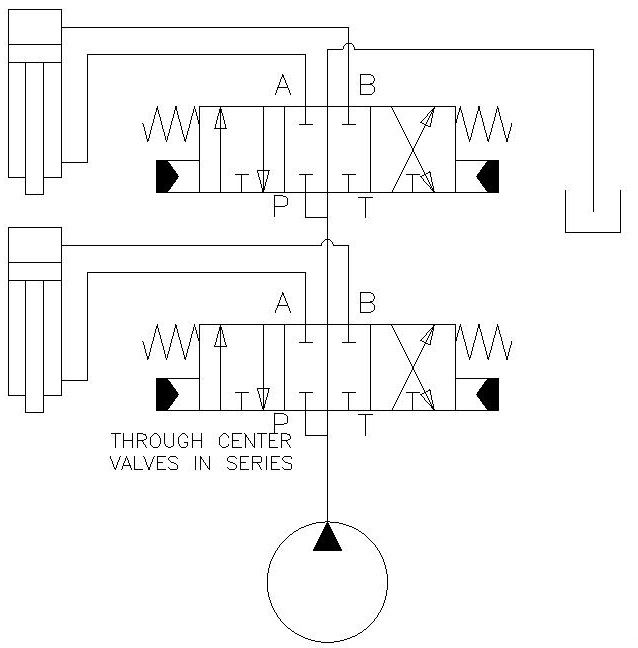

The Solution – Through Center Valve Configurations

What we want is to have a through center configuration which allows me use fresh pump oil for each valve section. So, when I close off my pressure port by shifting a valve, oil is cut off to downstream valve sections, and pressure can build for me to do work. The oil returning from the valve section goes directly to the tank. This provides safe and predictable operation of my system.

The other thing through center configurations allow me to do is better control multiple functions. Before, with a tandem center, I would be taking the oil out of this cylinder and powering the next one and that works for a very short period of time. But what I can’t do with that is flow share of any kind. A through center valve will allow me to feather any valve and get the desired behaviors I want.

With open center valves like these, there are limitations for performance. For starters, when two or more functions are selected, the flow per function drops. Also, the lowest pressure function will get all of the oil first. If you want other valves to get oil, you will need to back off the lowest pressure function. If this is an issue, you can look into using pre-compensated and post-compensated valves. They are more expensive and complex, but their multifunction capabilities are unmatched. But for our log splitter, like I said, it is very rare that I would split and use the jib at the same time. I am just not that coordinated, and I really can’t think of a reason to do it in the first place. I’m just going to leave it alone and be aware of the hazard.

I hope this explains why you would not want to use a tandem center for multiple valves.

Final Thoughts

In conclusion, there are three things that can happen when using a tandem center valve in series

- Increase in pressure

- Decrease in pressure

- Run out of oil

It avoid this, select a valve set that has a through center configuration. It will allow you to properly power many valve sections without these effects.