If you are anything like me, you have a deep desire to design and build things. If I had a nickel for every time my mother said, “Corey, what are you doing?” I would be set for life.

I love tinkering and it has lead to a trying, but rewarding career. (It has also gotten me in trouble too.) It is not surprising that I have spent most of my career in product development.

Yes, engineers do design products. However, most engineers do not work in a product development role. There are many other engineering roles such as testing, quality, applications and management, that are critical to the product’s success, but do not contribute directly to the design process.

Unfortunately, product design roles are a minority in the engineering community, but without them, there would be no new products. However, without engineers working around the product to produce it, there would be no sales to have a product in the first place.

It is a symbiotic relationship where a good product needs great sales, manufacturing and distribution. All of these components require competent engineers. This is a good thing because all of us have different skills to offer and excel at. I am a good design engineer, but I can guarantee that I would be a horrible quality engineer. That type of work is just uninteresting to me, but I know many other engineers who love the challenge of making production go smoother.

Let’s take a few minutes to look at all the disciplines of engineering needed to bring a product to market.

1. Design

So the design engineer is probably the most prominent and sought after roles as an engineer. Everyone wants to design something! A design engineer will need to be able to brainstorm, conceptualize and bring multiple systems together to work as one. These are not easy tasks.

A good design engineer will need to be good with all types of stress calculations, analyzing stress flow and finding ways to approximate things that are impossible to calculate. Another necessary skill is to be able to mentally see how a design works in time (the 4th dimension).

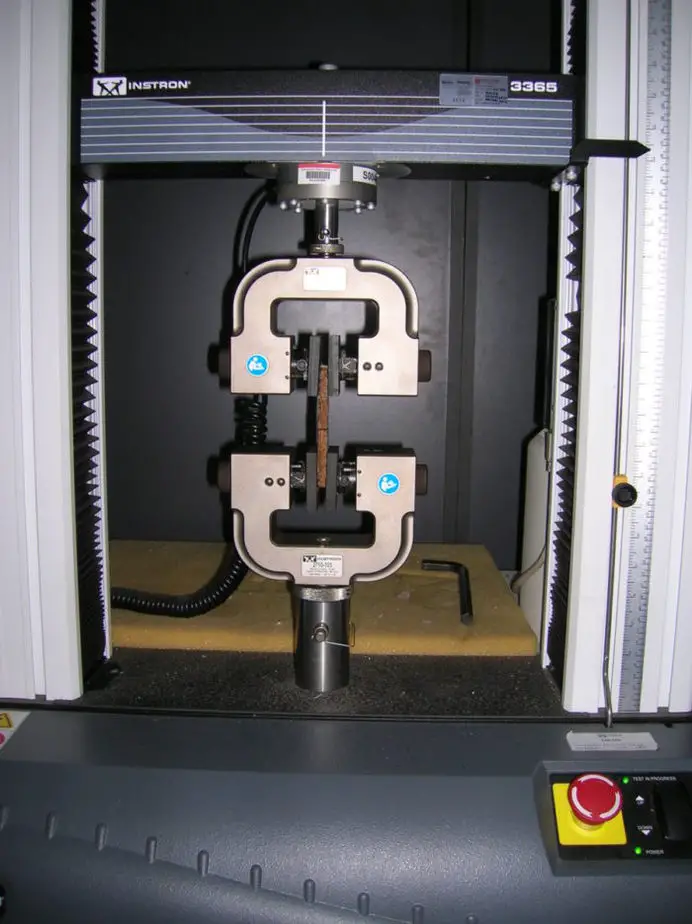

2. Testing

The testing engineer is the design engineers worst foe and the company’s best insurance policy. No one wants to launch a product that has a fundamental defect or doesn’t operate as intended.

Test engineers are responsible for examining products and / or software and finding ‘real world’ ways to break them or at least make sure they will last for the intended lifespan.

Test engineers will need to develop methods of testing products that may require high loads or cyclical loading patterns. You can also find out how to test for operation in high / low temperatures and weather conditions (mostly water).

3. Sales

Once you have a product, you need someone to sell it. Sales engineering will meet with customers to determine what the customer’s goal is and to suggest products that will solve their problem.

An engineering background comes in very handy here because you be able to grasp a full understanding of the product and what the customer wants to do. If you don’t know how a particular part of the solution would work, you are more likely to be able to identify this and bring others in who can answer the question.

If a non-technical person is in this role, you may sell a lot more product at first, but if it doesn’t meet the customer’s goal there won’t be any repeat business. You always want to make the customer have a pleasant experience so having a sales engineer is often the better choice.

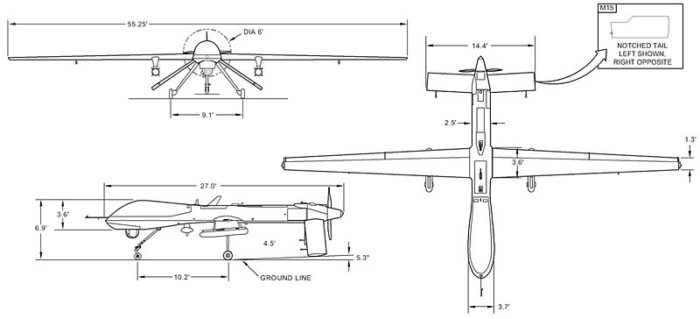

4. Applications

Because of the complexity of equipment that is on the market, many mid to high end products are not purchased, but applied. This is where the applications engineer comes in.

The engineer will usually meet with a customer and salesman and do a thorough investigation of what the project’s goals are and how to accomplish them. They will ask probing questions to make sure that the potential product is exactly what the customer needs.

After the sale, the applications engineer will customize an existing product(s) to the customer’s requirements. Sometimes these solutions will be fairly intense. The end result is a system that will not only meet the customer’s expectation, but it will also be a complete solution.

Applications engineers usually like this position because it allows them to meet with real people and get away from the desk. Applications engineers that interface with customers on a regular basis usually have a good idea of where their industry is headed.

Good examples of systems that are applied and not purchased are hydraulic valves and valve systems, electronic control systems, fabrication machinery or any other product that has a multitude of options.

5. Quality

The quality engineer has a tough road. They always seem to be caught in the middle of slowing (or stopping) production and the design engineers. Yes, there is a battle waged between getting the product out the door and making a good product.

Quality engineers put checks in the production process to prevent issues from happening. Many products will have a Failure Mode Effect Analysis (FMEA) done on it to identify places where a defect can start and how to detect it. From this analysis, a Control Plan is drafted as a set of rules to be followed to prevent defects. Work Instructions and Layered Process Audits are also developed as a way to keep training consistent and provide a routine inspection method.

It is imperative to have great quality engineers to ensure the long term success of your product.

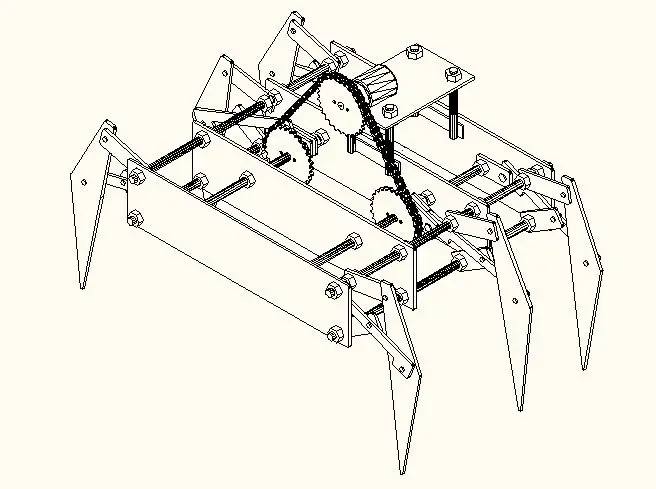

6. Research and Development

Often lumped in with the design engineer, research and development is a critical part of sustaining a business. Many businesses are profitable for a time and then the market shifts leaving them broke. Having a team of research engineers and keeping an eye out for market shifts is important. R&D engineers will be looking ahead and evaluating what new technologies are coming, but not ready for real world applications yet.

Many engineers are interested in being researchers because they will always be on the cutting edge of new technology. The greatest opportunity for a mechanical engineer in this field today is in the mechatronics and materials arena.

Development is a slightly different from research even though they are usually lumped together in the R & D department. Though they are lumped together, they are not the same. I am a strong developer or designer, but a so-so researcher.

A developer will usually build on the fundamental blocks of the research engineer and take a new product from a concept to production. This type of work has (hopefully) clear objectives, a firm timeline and project managers.

A researcher is responsible for making sure that a company is putting out products that will keep them in business many years in the future.

7. Management

The general career path of an engineer starts in the weeds doing more technical work and tends towards management. Generally speaking, it earns more money and at the rate that technology changes, it is difficult for even the most eager engineer to keep abreast of it long term.

There are two main types of managers within engineering, people managers and project managers.

People managers will oversee other engineers and drafters in a department. Many engineers may thrive here but the opposite is true as well. It is always a benefit to have a manager that is an engineer because he or she can relate to the team on a technical level. They also should have better communication skills to relay information to management and customers.

Project managers (PM) are there to keep projects on time and in the money. PMs love Gantt charts and checking bank statements to know when a project is behind or over budget (they all are).

Having a PM that is an engineer is a big help to the development team. I once had a non-technical PM who routinely pulled me aside to ask me basic technical questions. Great every once in a while, but annoying when it is three times a day on a two year project.

In Summary

Engineers do create products, but there are many other engineers needed to bring a product to market and keep it there. This is great news for all those who are interested in being and engineer, but don’t necessarily want to design.